Anyone who works in the manufacturing and shipping of corrosion-sensitive merchandise can understand the importance of ensuring that this merchandise is packaged and stored correctly. As these items are often sensitive to external changes, such as humidity, they must be properly protected to reach their final destination in their original condition. The most popular solution for humidity control remains the use of container desiccant for a variety of items.

What are container

desiccants?

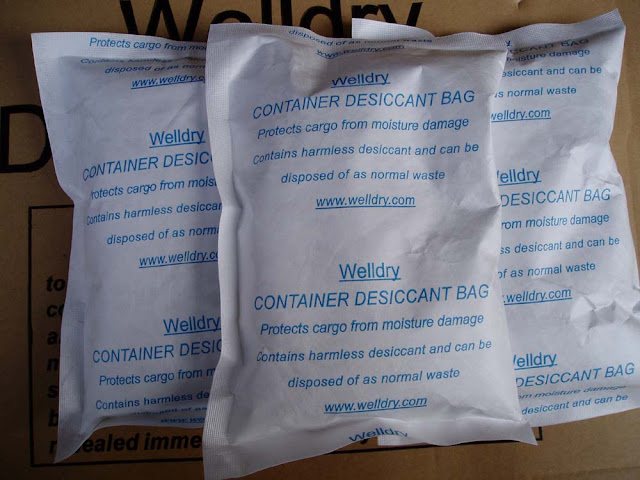

So, what exactly are container desiccant? Whether you know their name or not, you've probably come

across them on items you've bought. They are used for packaging anything like

slippers or sensitive electronics. As the name implies, desiccants absorb

excess moisture in the air, ensuring that goods do not deteriorate due to

moisture damage or corrosion while still in their original packaging. Although

silica is one of the best-known desiccants, other options are also available,

with different shapes or sizes to meet any need.

How do container

desiccant work?

Container desiccant

are placed inside the aluminum packaging to remove any moisture, protecting the

merchandise once it is packaged. In addition, these packages contain a drying

agent, which ensures that any excess moisture is absorbed by the desiccant and

not by the product inside the package.

Maintain the

quality of the merchandise

Container desiccant

can form an important part of the packaging process, ensuring that the items

you manufacture reach the customer in their original condition without damage

or deterioration in quality. In addition, as container desiccant vary in size

and shape, they offer a versatile solution for most humidity levels, making

them a popular solution among manufacturers in many industries.

If you are considering

investing in container desiccant, our range, made from activated clay, has many

applications and can be used with both military and commercial products to

protect against moisture damage. Remember, if you have questions or would like

more information, our team is here to help.

We recommend you to

visit protective

packaging company like Britwrap

for more information.

Why use moisture

barrier packaging?

Moisture barrier

sheets are a niche product; you may never have heard of them. However, one

thing is certain, the applications for its use are limitless.

Moisture content

influences the physical properties of a substance, such as weight, density,

viscosity, refractive index, and electrical conductivity, among other things.

So, when your customer is going to process that highly specialized polymer or

specialty chemical, you've carefully manufactured moisture content is key.

Barrier sheets have a

transmission rate 80 times lower than a standard polyethylene liner. To you and

me, that means it's 80 times more effective at keeping moisture out. It also

works the other way. If you want to retain a particular moisture content of

your product, a Barrier foil liner will prevent your product from drying out.

Dry product protection

is not the only arena where barrier sheets are king. Corrosion prevention is

another key application to which he lends his hand. A barrier foil coating

sealed with a carefully calculated amount of desiccant will ensure that the

relative humidity is kept well below 40%, where corrosion of metals will occur.

3D Barrier Bags can even attach an indicator to your barrier foil bag so you

can monitor this.

Comments

Post a Comment